"As access to FUSION's wind tunnel provides us with a unique opportunity to optimize our equipment and enhance our riders' performance, we have high expectations for what this can develop into."

- Thor Hushovd

We are proud to unveil the world’s first in-house wind tunnel dedicated to sportswear development. This state-of-the-art facility allows us to conduct daily aerodynamic testing, enabling continuous refinement of our products. By integrating this advanced testing directly into our development process, we accelerate innovation and ensure our sportswear meets the highest performance standards.

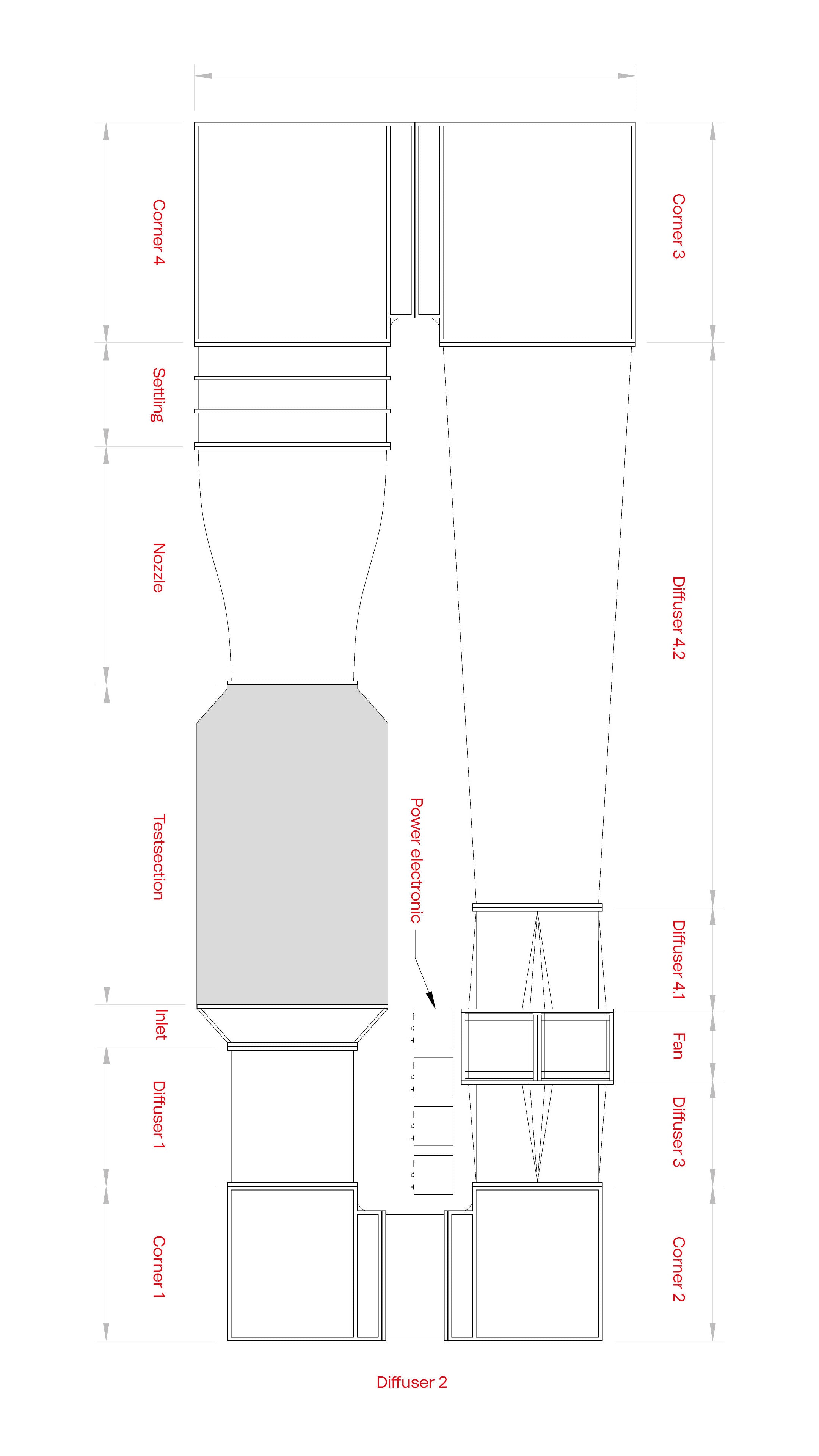

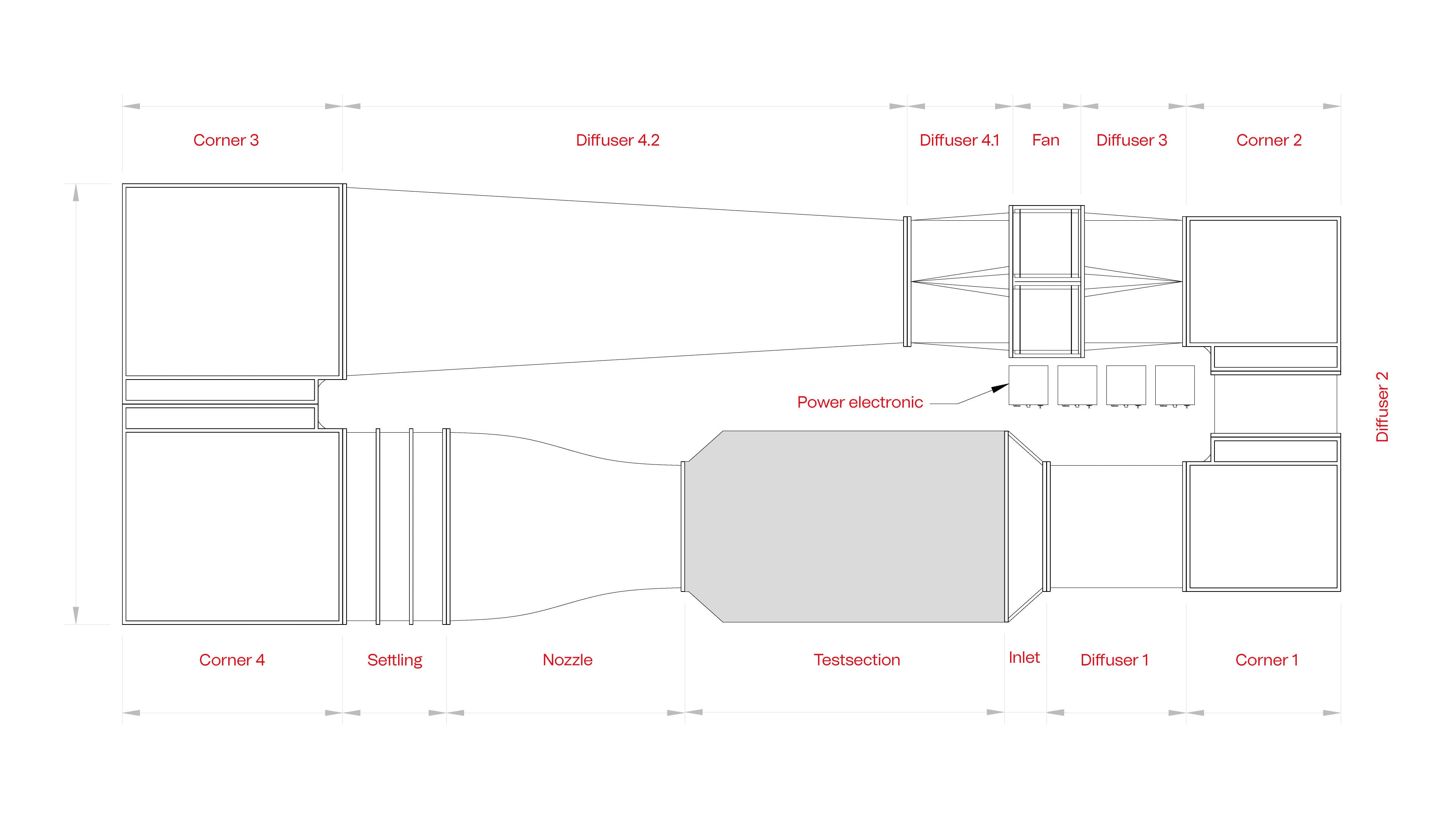

The outlet where the air is compressed before being directed into the test section.

The outlet where the air is compressed before being directed into the test section.

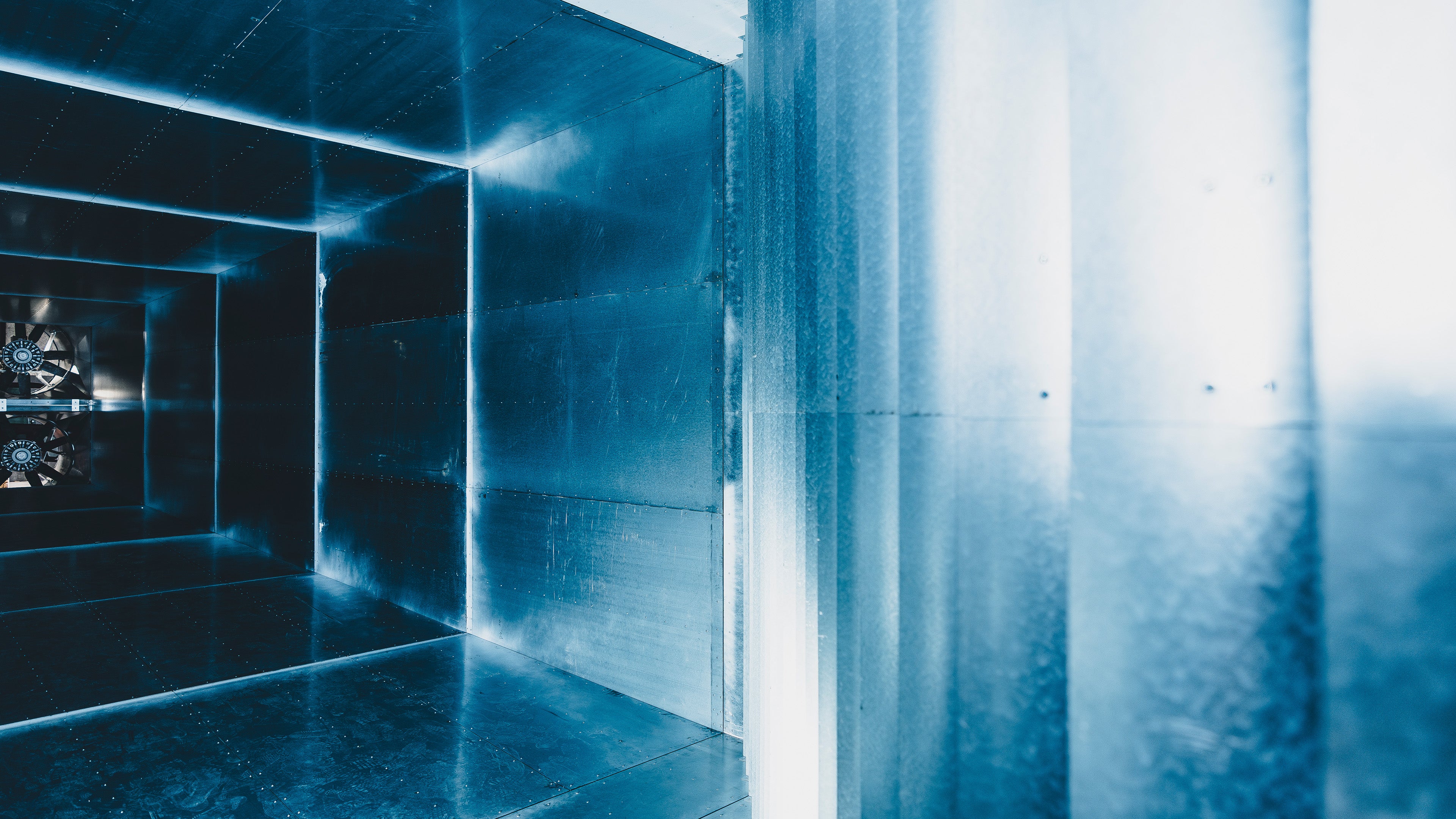

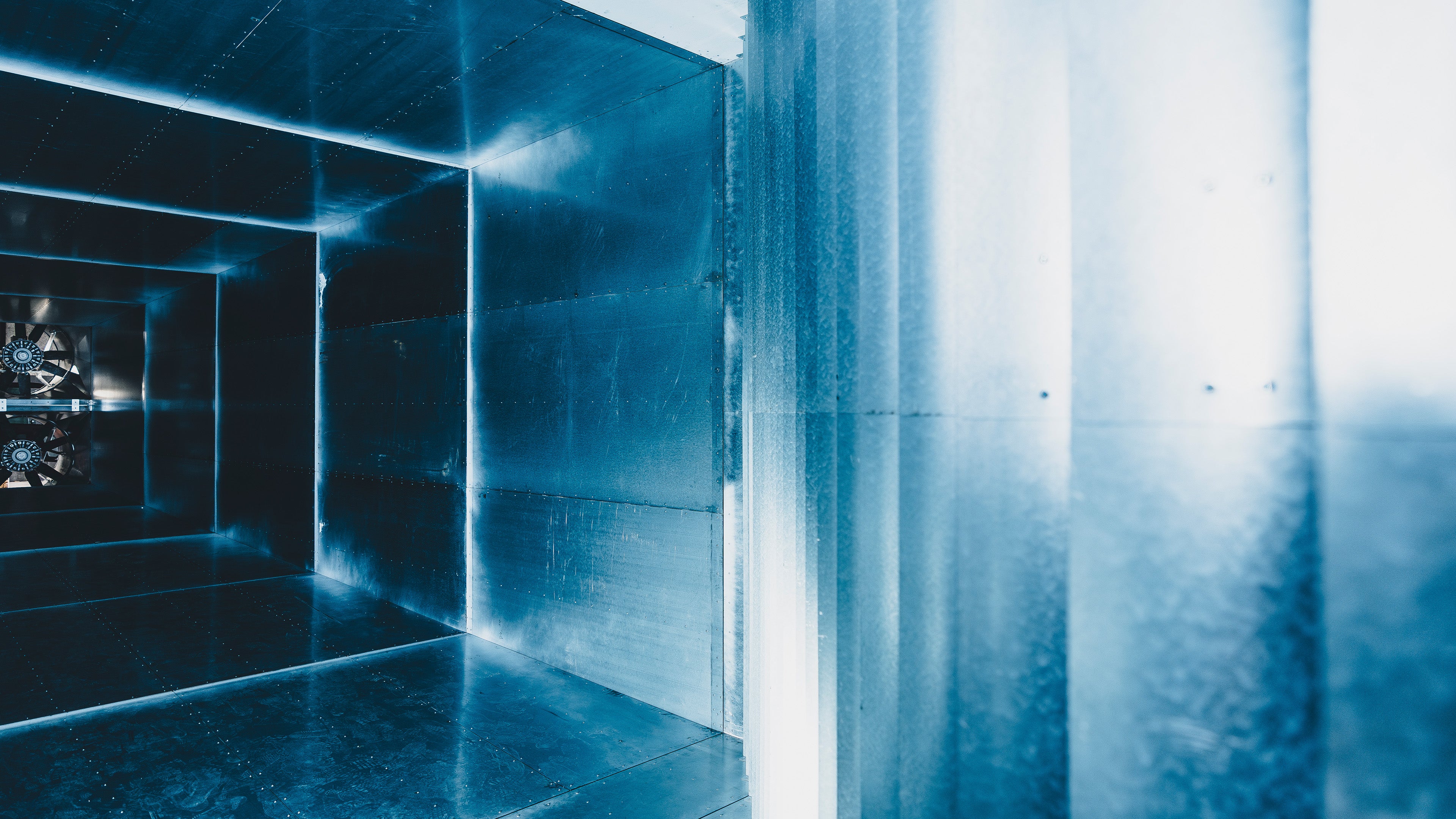

The area where the object or rider being tested is located. In the test section, the test object is placed on a Force Balance. The test section is described by the height, width, and length of the open testing area. Also referred to as the Working Section.

The area where the object or rider being tested is located. In the test section, the test object is placed on a Force Balance. The test section is described by the height, width, and length of the open testing area. Also referred to as the Working Section.

Gathers the air after the test section and redirects it back into the wind tunnel.

Gathers the air after the test section and redirects it back into the wind tunnel.

A series of settling screens ensure that the air's velocity is uniform and that turbulence is reduced before entering the contraction section.

A series of settling screens ensure that the air's velocity is uniform and that turbulence is reduced before entering the contraction section.

These assist in guiding the air around the corners of the wind tunnel.

These assist in guiding the air around the corners of the wind tunnel.

These assist in guiding the air around the corners of the wind tunnel.

These assist in guiding the air around the corners of the wind tunnel.

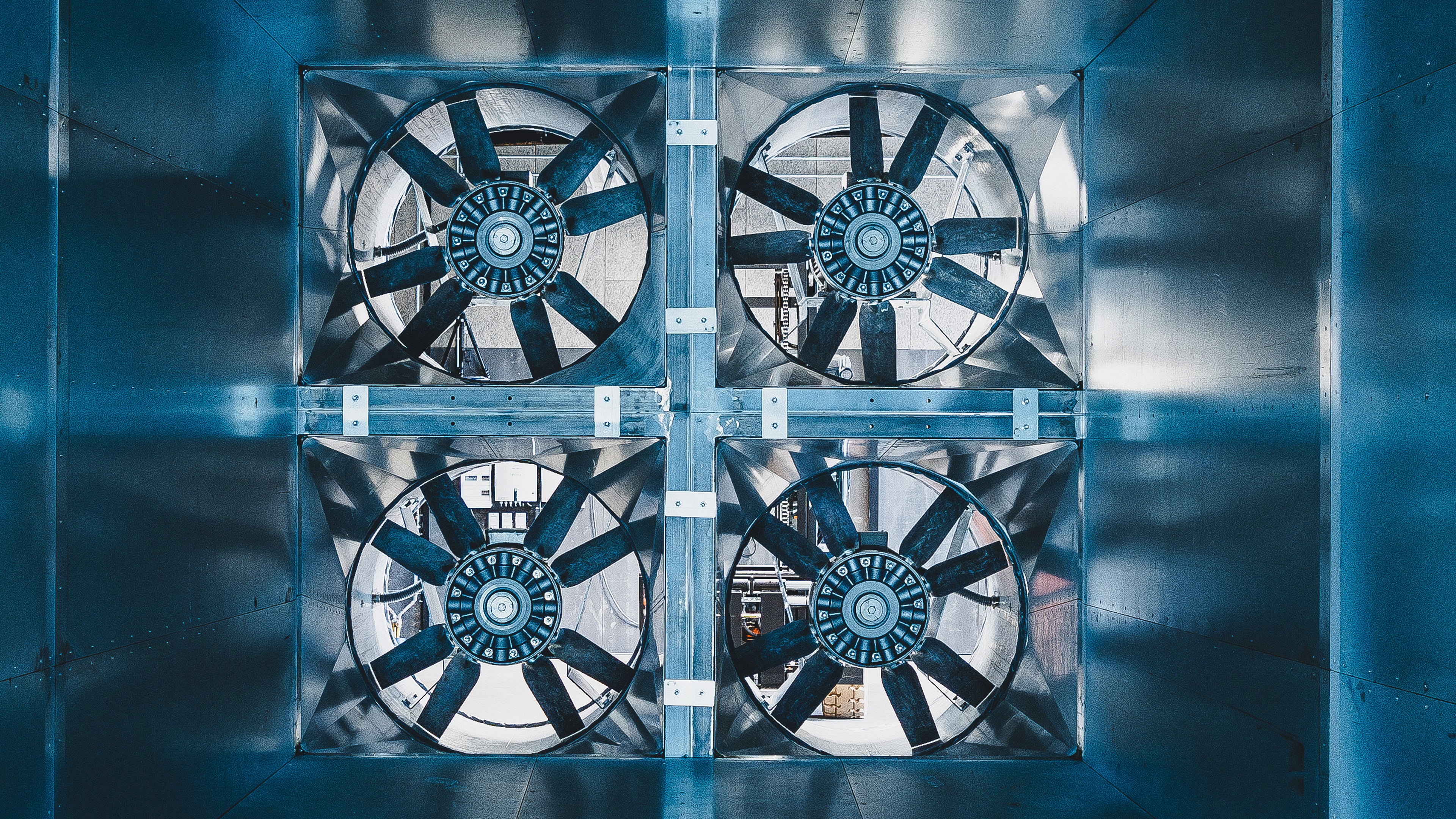

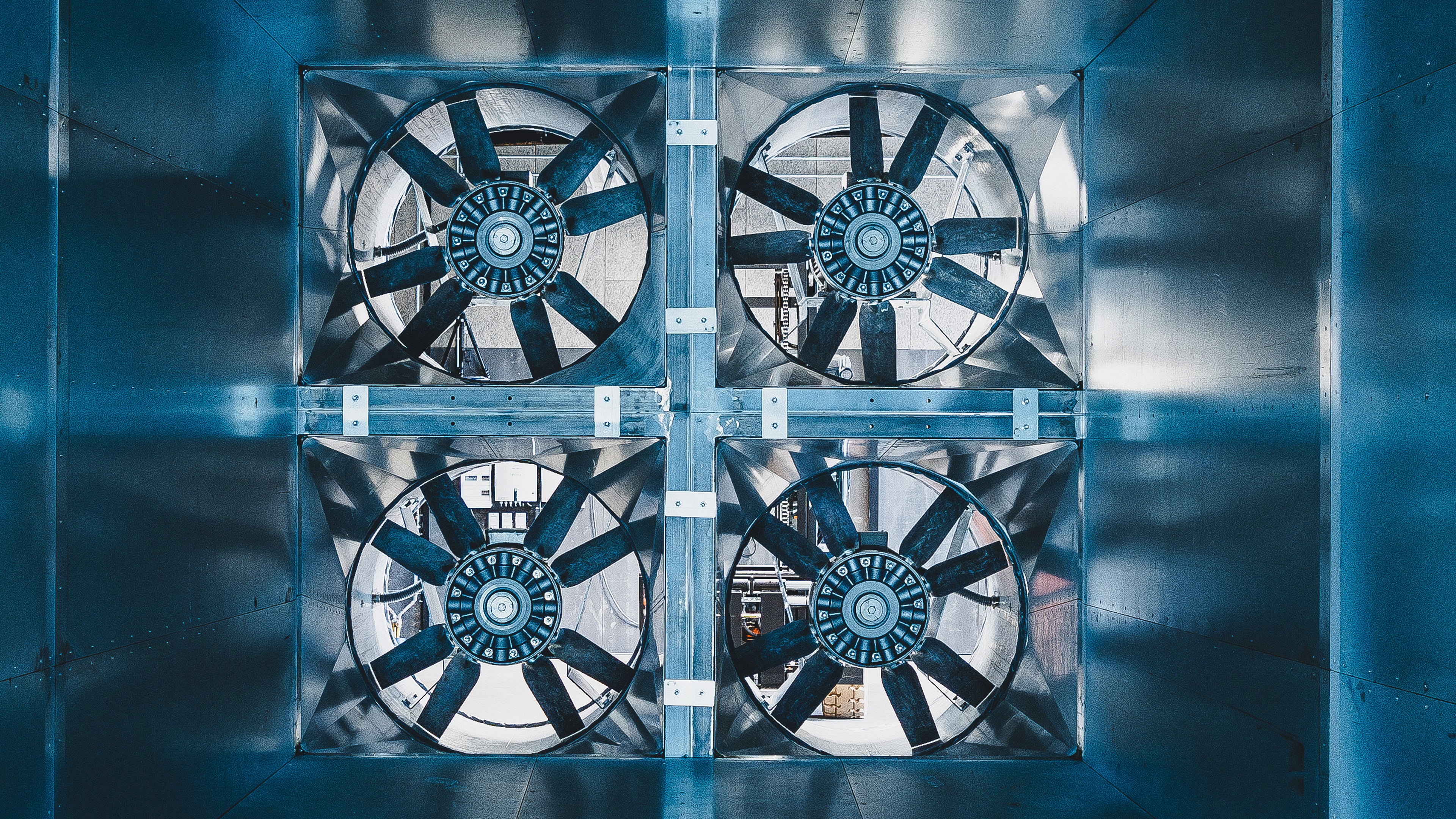

From here, the wind tunnel's air is generated and circulated within the wind tunnel.

From here, the wind tunnel's air is generated and circulated within the wind tunnel.

From here, the wind tunnel's air is generated and circulated within the wind tunnel.

From here, the wind tunnel's air is generated and circulated within the wind tunnel.

These assist in guiding the air around the corners of the wind tunnel.

These assist in guiding the air around the corners of the wind tunnel.

These assist in guiding the air around the corners of the wind tunnel.

These assist in guiding the air around the corners of the wind tunnel.

At FUSION, everything we do happens within a few hundred meters. From our TEMPO! Wind Tunnel to our Prototype Sewing Studio, Testlab, Performance Center, and Warehouse, this close-knit setup is designed to accelerate the entire process of creating performance sportswear.

The proximity of our facilities means testing insights can quickly turn into prototypes, adjustments, and finished products. For example, ideas tested in the wind tunnel can be refined in the Testlab, sewn into prototypes, and retested within days. This streamlined workflow allows us to react faster, explore new possibilities, and ensure every product is rigorously tested and ready for athletes.

By having our key facilities so closely connected, we can innovate and evolve at a pace that sets us apart—making the TEMPO! Wind Tunnel not just a testing tool, but a central piece in how we create gear that performs when it matters most.

Nestled within our Research and Development (R&D) department, the Prototype Sewing Studio is where technical innovation takes shape—literally. Where concepts move from the drawing board to tangible prototypes, ensuring every idea is tested, refined, and brought to life with precision. Whether it’s a new fabric, a reimagined fit, or a completely groundbreaking design, this place is central to the process, allowing us to fine-tune products before they reach athletes. By integrating sewing and prototyping into our R&D process, we ensure our gear doesn’t just meet expectations—it surpasses them. This is where world-class sportswear begins, helping to set new standards and pave the way for record-breaking performance.

Nestled within our Research and Development (R&D) department, the Prototype Sewing Studio is where technical innovation takes shape—literally. Where concepts move from the drawing board to tangible prototypes, ensuring every idea is tested, refined, and brought to life with precision. Whether it’s a new fabric, a reimagined fit, or a completely groundbreaking design, this place is central to the process, allowing us to fine-tune products before they reach athletes. By integrating sewing and prototyping into our R&D process, we ensure our gear doesn’t just meet expectations—it surpasses them. This is where world-class sportswear begins, helping to set new standards and pave the way for record-breaking performance.

Our Testlab is where "intelligent" fabrics are brought to life. We explore advanced material technologies, improving existing products and developing new ones that blend comfort, performance, and reliability. Every fiber, weave, and seam is examined for its ability to withstand the harshest conditions athletes face, ensuring that our products don’t just perform—they endure. The proximity to our wind tunnel allows seamless collaboration between aerodynamic testing and fabric innovation, accelerating the development of sportswear that is both high-performing and incredibly durable. The FUSION Testlab isn’t just a laboratory; it’s the starting point for gear that’s built to last and proven to perform.

Our Testlab is where "intelligent" fabrics are brought to life. We explore advanced material technologies, improving existing products and developing new ones that blend comfort, performance, and reliability. Every fiber, weave, and seam is examined for its ability to withstand the harshest conditions athletes face, ensuring that our products don’t just perform—they endure. The proximity to our wind tunnel allows seamless collaboration between aerodynamic testing and fabric innovation, accelerating the development of sportswear that is both high-performing and incredibly durable. The FUSION Testlab isn’t just a laboratory; it’s the starting point for gear that’s built to last and proven to perform.

The FUSION TEMPO! Wind Tunnel is where we test and refine our sportswear to ensure it performs in real-world conditions. From fabric behavior to rider position, every detail is analyzed to reduce drag and improve efficiency. With the ability to test daily, we can make quick adjustments and see immediate results. This hands-on approach allows us to create products that are scientifically tested and proven to help athletes perform at their best.

The FUSION TEMPO! Wind Tunnel is where we test and refine our sportswear to ensure it performs in real-world conditions. From fabric behavior to rider position, every detail is analyzed to reduce drag and improve efficiency. With the ability to test daily, we can make quick adjustments and see immediate results. This hands-on approach allows us to create products that are scientifically tested and proven to help athletes perform at their best.

The Performance Center is where our team stays active, builds strength, and enjoys training together—whether through joint Zwift rides or team workouts. It’s also a space where visiting athletes can keep up with their training routines without missing a day. This simple, practical space reflects our commitment to growth, both as individuals and as a brand. By staying active and engaged, we ensure our team and our products continue to evolve and improve.

The Performance Center is where our team stays active, builds strength, and enjoys training together—whether through joint Zwift rides or team workouts. It’s also a space where visiting athletes can keep up with their training routines without missing a day. This simple, practical space reflects our commitment to growth, both as individuals and as a brand. By staying active and engaged, we ensure our team and our products continue to evolve and improve.

Our warehouse is the epicenter of precision and efficiency. With a remarkable 99% daily order fulfillment rate, we ensure that our customers' needs are met accurately and promptly. Our meticulous approach combines automation and cutting-edge technology to minimize errors and enhance efficiency, guaranteeing that every product leaving our Warehouse meets our highest standards. We receive shipments from our Lithuanian production studios twice a week and dispatch goods to both B2C and B2B customers daily, ensuring swift and accurate deliveries

Our warehouse is the epicenter of precision and efficiency. With a remarkable 99% daily order fulfillment rate, we ensure that our customers' needs are met accurately and promptly. Our meticulous approach combines automation and cutting-edge technology to minimize errors and enhance efficiency, guaranteeing that every product leaving our Warehouse meets our highest standards. We receive shipments from our Lithuanian production studios twice a week and dispatch goods to both B2C and B2B customers daily, ensuring swift and accurate deliveries

At FUSION TEMPO! Wind Tunnel, we work hand-in-hand with world-class triathletes and professional cycling teams to drive sportswear innovation. These elite athletes bring invaluable real-world experience and performance data, allowing us to refine every aspect of our designs. Their participation in wind tunnel testing provides direct feedback on garment fit, aerodynamic efficiency, and material behavior under race conditions, ensuring our products meet the demands of the highest levels of competition.

Having our own wind tunnel, located at our headquarter enables continuous testing—day in, day out. This unmatched access means we can test, analyze, and improve in real-time, ensuring no opportunity for performance gains is missed. By blending the insights of athletes with the precision of cutting-edge testing, we create sportswear that is scientifically validated and race-proven, giving our athletes—and every customer—an undeniable edge.

F A Q

FAQ

What is the TEMPO! Wind Tunnel®, and why is it important?

The FUSION TEMPO! Wind Tunnel® is a purpose-built aerodynamic testing facility designed to optimize sportswear and cycling equipment. Unlike traditional wind tunnels, it focuses exclusively on the unique needs of endurance athletes, enabling precise testing to improve speed, efficiency, and performance.

Why does aerodynamic drag matter in cycling, running and triathlon?

Aerodynamic drag is the resistance athletes face when moving through the air. It accounts for a significant portion of the effort in cycling and running, especially at higher speeds. By reducing drag, athletes can go faster with less energy or maintain their speed with greater efficiency.

How does Fusion test its products in the wind tunnel?

We use a structured approach: small, focused batches of 2-3 products are tested repeatedly to ensure consistent results. Each session evaluates fabric textures, body shapes, and product designs to refine and optimize performance step by step.

Can wind tunnel testing help create personalized sportswear?

Yes. Wind tunnel testing allows us to tailor sportswear to different body shapes, athletic disciplines, and performance goals. For instance, we can design garments specifically for high-speed cycling or endurance running based on individual needs and preferences.

What makes the TEMPO! Wind Tunnel® different from others?

Most wind tunnels are adapted from industries like automotive or aerospace, often requiring compromises for sports applications. The Fusion Wind Tunnel was designed from the ground up for cyclists and runners, ensuring the airflow, sensors, and testing conditions accurately simulate real-world performance.

How does textile design impact aerodynamics?

Textiles play a critical role in reducing drag. Specific textures and materials can manipulate airflow, improving efficiency at different speeds and conditions. The wind tunnel enables us to test how fabrics interact with air and adjust their design for maximum performance.

Why isn’t all testing done outdoors?

Outdoor testing is inconsistent due to variable factors like wind, weather, and terrain. The wind tunnel creates a controlled environment where we can repeatedly test and refine products with scientific accuracy, ensuring reliable results.

What is CDA, and how does it relate to performance?

CDA (Coefficient of Drag Area) measures how much drag affects an athlete at a given speed. It’s calculated by dividing drag force by air pressure. A lower CDA means an athlete can move faster with the same effort, making it a key metric in performance testing.

How does Fusion use wind tunnel data to improve its products?

The wind tunnel provides precise data on aerodynamics, fabric performance, and body positioning. We use this data to innovate new designs, adjust existing products, and create sportswear that is scientifically proven to enhance speed and efficiency.

What are “marginal gains,” and why are they significant?

Marginal gains refer to small, incremental improvements that add up to significant performance boosts. In competitive sports, these gains can be the difference between winning and losing. The FUSION TEMPO! Wind Tunnel® helps us identify and capitalize on these opportunities.